INEOS Olefins & Polymers Europe claims it has become the ‘first polymer producer in the world’ to successfully commission a new pilot line to co-develop recyclable flexible packaging films with customers.

The company states that the multi-million euro investment could help to prevent around one million tonnes of waste from being sent to landfill each year, according to The Circular Economy for Flexible Packaging (CEFLEX).

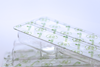

The new multilayer, blown film line with Machine Direction Orientation (MDO) has been installed at INEOS’ R&D centre in Brussels, Belgium. It enables customers to carry out full-scale tests without losing production capacity on their own lines.

The technology, supplied by Hosokawa Alpine, heats and stretches polymer films to improve their physical and barrier properties, enabling them to be used in different product applications. The first collaboration projects are reportedly already under way, developing new films to be applied directly to customer production lines.

INEOS says that today’s multi-material packaging films combine different polymers, each performing different functions, but which in combination make the film difficult to recycle. It adds that making simpler films with the same performance means the new packaging can be more easily recycled to meet the requirements of the EU Packaging and Packaging Waste Regulation.

Rob Ingram, CEO of INEOS Olefins & Polymers Europe, said: “Flexible packaging films play a valuable role in society, but we recognise and share people’s concerns about plastic waste. Every day we work alongside stakeholders across the value chain who share our commitment to a circular economy, developing more sustainable solutions to consumers’ needs. Fully recyclable films are a big development and I’m excited about the possibilities created by our investment in this new MDO line.”

In related news, Berry Global’s flexibles division announced that it has increased its recycling capacity across three of its European recycling facilities as part of a pan-European project to expand production of its Sustane range of recycled polymers. The company says many of the products manufactured at its European films facilities now contain more than 30% recycled content, such as Stretch Hood, NorDiVent vented sacks, FormiFor compression films and peat films for gardening substrates.

Evertis has launched its Evercare brand of medical-grade films with recycled, recyclable, and biobased contributions – a move expected to upgrade packaging performance, enhance sustainability, and comply with regulations in the healthcare industry. The films are designed to improve mechanical and optical properties and increase resistance to sterilization in thermoforming applications.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

The ultimate guide to global plastic sustainability regulation

No comments yet