Henkel has revealed that most of its Bref toilet rim blocks in Europe utilize materials ‘partially based’ on renewable raw materials for the cleaning balls and rim block cages, through a mass balance approach.

According to the company, the process involves replacing a certain amount of fossil raw materials with renewable raw materials at the start of the manufacturing process. The quantity of renewable raw materials is then allocated to specific products using a certified calculation method.

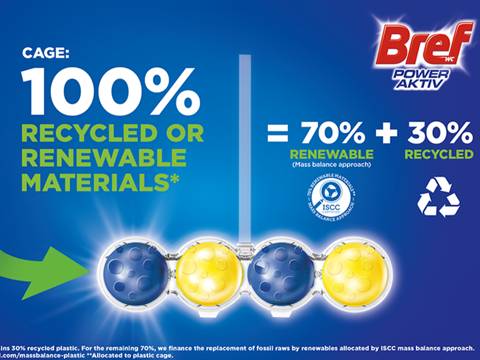

Henkel says it uses renewable raw materials for the plastic cages surrounding the toilet rim blocks, with the baskets already consisting of 30% recycled plastic. For the remaining 70% of virgin plastic (excluding colour granules for coloured plastic cages) which cannot yet be replaced by recycled material ‘due to availability, safety, or aesthetic reasons’, the company is investing in collaboration with its suppliers to increase the proportion of renewable raw materials for plastic production.

Compared to conventional fossil-based virgin plastic, Henkel states the plastic based on renewable raw materials will come with a lower CO2 footprint amounting to more than 10,000 tonnes in annual CO2 savings (based on sales figures from the previous year). The company adds that in partnership with Moeve, it has recently succeeded in using a new surfactant for producing most of its toilet rim blocks, made from 68% renewable raw materials according to the mass balance approach.

In April, drinkware manufacturer First Editions unveiled its reuseable coffee cup concept, FOAMO, made from renewable plant-based polypropylene and created using all-electric injection moulding machinery from Sumitomo (SHI) Demag. The cups are made from a renewable feedstock food-grade polypropylene created from 70% waste, such as cooking oil.

More recently, Elopak, Orkla Home and Personal Care (OHPC) and Dow launched a new line of cartons containing a mix of recycled polyethylene and bio-circular (renewable) polymers. The thin plastic layer in the cartons will initially contain 10% post-consumer circular polyethylene (PE), with the other 90% supplied from bio-circular polymers sourced from vegetable-based waste, such as used cooking oil.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet