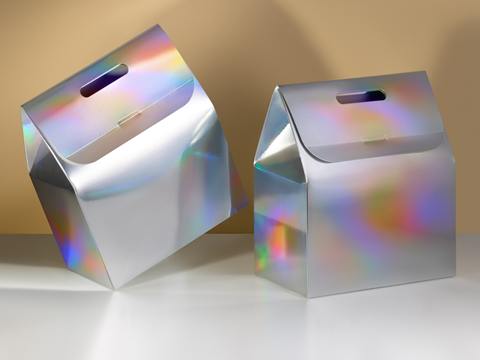

Holography is sometimes incorporated in packaging for its visual elements and as a security measure. Journalist Frances Butler takes a look at the use of holography in applications such as tapes, labelling and stickers, how companies are utilizing it for shelf appeal and anti-counterfeit purposes, and raises the question of its recyclability.

In terms of labelling, Australian plastic packaging company Caps & Closures launched the ID-Shield holographic labelling and decoration system in 2022, designed to prevent copying of a brand’s product labelling. The ID-Shield processed surface reflects light at different angles resulting in a holographic image, with the solution apparently fully integrated into the packaging during manufacturing, with no added materials, adhesives, inks or printing processes. The company claims this eliminates potential label contamination in the recycling stream.

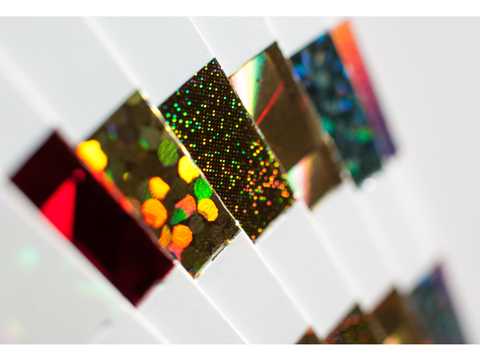

Thai company Packtica makes hologram labels and stickers including 2D, 3D dot matrix and Russle hologram options which can incorporate smart QR codes and serial numbers. When it comes to brand protection, Packtica says its Smart QR hologram labels make it harder for products to be counterfeited, as its holographic laser technology makes them unique.

From a consumer standpoint, holograms enable identification and verification of a product’s authenticity, serving as “visible proof of legitimacy” which “instills confidence in consumers” when purchasing. In future, the company predicts consumer product authentication will become quicker and more accurate through the increasing availability of smartphone enabled hologram verification apps. It also cites advancements in nanotechnology and 3D printing as potential avenues for the development of more sophisticated, customizable holograms.

Graphic Packaging International offers holographic effects aiming to improve packaging’s visual impact on the retail shelf with various design elements, such as lines and waves, and to act as an anti-counterfeit measure due to being hard to replicate due to the “specialized nature of the process.” The company provides cast and cure finishing (lasergloss) as an option, which can be applied on dedicated spots, larger areas and on top of graphics or metallic effects. It adds that the finishing does not affect the packaging’s recyclability, as no film is left on the surface.

Holography as an anti-counterfeit measure

The use of holography as an anti-counterfeit measure was discussed by Dr Paul Dunn, chair of the International Hologram Manufacturers Association, in an article for The European Pharmaceutical Review, focusing on its applications in pharmaceutical packaging. He gave the example of blister packs, where some holograms can be designed so that they are only visible behind each pill or capsule cavity on the back of each pack, allowing the printing of dosage and marketing information on the area surrounding the pill or capsule recess.

Dunn argued that this gives consumers the ability to validate the authenticity of their purchases with the use of custom holograms. He added that holography can also be integrated with secure web interfaces to help eliminate rogue ordering of products while authorised distributors can pick, pack and ship items in carefully measured quantities to customers, with the product’s movements throughout the supply chain fully tracked and documented.

The use of holography in tapes

Holographic elements can also be used in tapes. Earlier this year, Filtrona Tapes announced its range of holographic tear tape, Supastrip Prism, which is applicable to flexible plastic or paper packaging across various FMCG applications like pet food, personal care, food-to-go and frozen food. The company says Prism Plus combines holographic films with print for on-pack branding, Prism Ultra offers customised on-pack de-metallized or selectively metallized holographic effects, and Prism Unique provides bespoke hologram designs for security and brand protection.

We spoke to Sarah Rutland, market development manager at Filtrona Tapes, to learn more about this range and the wider role of holography in tapes. On the decision to use holographic elements in tapes, Rutland says the ability to design features to stand out using holography while maintaining the “easy opening benefits” of the Supastrip range has a compound effect, as the tapes can be customized to include built in security and brand protection without changing the primary packaging.

According to Rutland, if you change the tape and not the pack, holography becomes “commercially acceptable without compromising on functionality or aesthetics.” She adds that the Prism range can be customized with logos and colours to match a company’s branding, enabling consumers to recognize a brand at the point of sale and help them make quick decisions about products.

When it comes to shelf appeal, Rutland believes holography can help give brands an edge. She says that when consumers stand in front of a shelf filled with products, they are bombarded with visual messaging from dozens of brands, and that’s only in store. “It’s estimated that consumers see around 10,000 marketing messages every day,” she emphasizes. “The eternal question for any brand is: how do you make yours stand out?”

According to Rutland, achieving success in a crowded market means product packaging has to catch the eye of the consumer - and project a sense of quality they can trust - within about 20 seconds, by which time the shopper will have already made their mind up. She states:

“Brands need to use every tool at their disposal to make the most of that 20 second window, and few tools are more useful in this process than holographic effects. As basic as it sounds, people tend to like shiny things.”

Filtrona Tapes’ Prism Unique tape is said to have bespoke hologram designs for security and brand protection. We asked Rutland about some of the applications for this and how the security features work. She pointed out that in today’s market around 80% of consumers are estimated to have come into contact with fake goods, knowingly or not, and a study by brand protection agency Incopro revealed that although 19% of UK consumers willingly purchase fake goods, most are unwilling participants and this can significantly damage a brand’s reputation.

With the company’s Prism Unique tapes, layers of overt and covert security can be incorporated into holographic films, such as embedding microtext, nanoimages, and image switches. Rutland claims using a tear tape as part of an anti-counterfeiting strategy offers cost and efficiency benefits, as in a scenario where counterfeiters crack your deployed features, “tear tapes offer the possibility of a quick retaliation to change and update the tape design, rather than the full pack.”

When it comes to the recyclability of the tapes, Rutland says this should be viewed along with the packaging it is deployed on, as it is affixed to the packaging and will be recycled alongside the base material. In her view, this means making general statements about the tape itself is difficult in the flexible packaging space, as it could be attached to multiple different substrates in different quantities.

As for the future of holography in packaging materials, Rutland states that harnessing the consumer understanding of holograms as an authentication feature and blending it with an interactive, intuitive method of consumer validation of authenticity remains a sought-after development area. She concludes:

“From a decorative standpoint, using holography as an engagement tool to provide on-shelf differentiation is still a very desirable solution. Ensuring it stays that way will mean developing cost-effective effects, reducing waste and making verifiable sustainability claims will be essential.”

Security, tracking and shelf appeal: holographic packaging in 2024

This year several companies have introduced holographic elements into their packaging. In January, All4Labels Global Packaging Group launched INTEGRITAG, designed to implement secure and intelligent features into digital printing solutions to enhance protection, transparency, efficiency, and sustainability across supply chains.

Apparently, INTEGRITAG combines RFID from Rako Secure, holographic security labelling via the Hologram Company, and Centro Grafico’s high-security labelling to manufacture secure label solutions. These technologies are expected to fit into existing products or packaging to tackle product fraud, security threats and streamline the efficiency of supply chains.

The tag is said to offer real-time tracking across the supply chain and seeks to keep authentic products out of the grey market to protect brand revenues – offering smart labels, holographic security products, QR Fingerprint, EAS, SaaS & Data Analytics, and embossing base foils.

A few months later, KURZ revealed its TTR NOVA solution, including holographic thermal transfer ribbons that aim to enhance product labels with diffractive finishes and dynamic depth effects. We asked Ivo Kionka, CEO at KURZ Typofol, about the innovation.

Kionka stated the solution had started with seven designs, with more to follow. The product line is suited for full-surface decoration as well as fine details and can be overprinted. Kionka added that it can be used on various substrates, particularly for durable marking and finishing of labels, credit cards and coated paper.

The solution is designed to be a cost effective and ‘easy to implement’ for enhancing labels and packaging using existing equipment. When asked what differentiates the product from existing solutions, Kionka said:

“Hot stamping or cold transfer was previously required to add a holographic effect to labels and packaging whose marking is applied using TTR. With NOVA, this is no longer the case, as only a conventional flat-head printer is required.”

It seems that holography is mostly being utilized in packaging for its shelf appeal and anti-counterfeit purposes, particularly when it comes to security and brand protection. There is also potential for its use in the pharmaceutical industry, in applications such as blister packs. In all areas, the use of holography appears to increase consumer and company confidence in the security and authenticity of a product – whether it’s the incorporation of security measures, the effect itself being difficult to replicate or its visual appeal on retail shelves, it will be interesting to see how holographic effects continue to be utilized in packaging and if there is expansion into other areas in future.

No comments yet