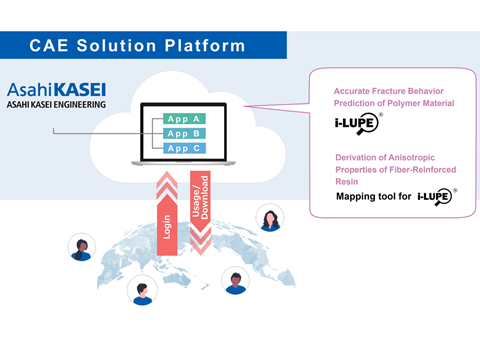

Asahi Kasei Engineering (AEC) has launched a cloud-based computer aided engineering (CAE) solution platform, with apps to predict the crash and impact behaviour of polymers.

The company states that as the adoption of polymer materials in automobiles and other products increases, precise simulation of material behaviour will help to enhance product design and reduce time and costs for material and application development. It adds that cloud-based high-performance computing (HPC) is being increasingly used throughout various industries, and on-demand use of computer aided engineering (CAE) software installed in cloud HPC as software as a service (SaaS) is becoming more common in the material development process.

The apps offered on the platform include the downloadable polymer material fracture prediction model i-LUPE. Asahi Kasei explains that microscopically, amorphous polymer materials have a structure in which molecular chains are entangled. When an impact or other force is applied to this material causing significant deformation, the molecular chains are stretched, resulting in the formation of voids and fibrils (bundles of molecular chains).

The company states that when these so-called ‘crazes’ grow, the polymer material fractures. By focusing on these crazes, i-LUPE can apparently predict and reproduce possible resulting fractures in the polymer.

As a supporting app to i-LUPE, the CAE solution platform has an on-demand mapping tool specifically focused on anisotropic materials such as fibre-reinforced resins. The tool is said to convert fibre orientation data into i-LUPE material property lists.

Asahi Kasei says these lists are used as a reference for selecting the optimal material for specific applications, resulting in an accurate visual representation of the deformation behaviour of fibre-reinforced resins.

In similar news, Avery Dennison and TripleR teamed up with Aquinos Group in January to tag its bedding materials via the atma.io connected product cloud, aiming to ensure their digital identifiability and management. From 2024, Aquinos Group will be tagging its products with digital ID technology, involving a ‘digital twin’ with precise product information, which can then be used to share information about their origins and material composition across the circularity chain.

More recently, Antares Vision Group introduced its cloud-based Food Safety Solution, designed to improve regulatory compliance, precision traceability and supply chain transparency for food and beverage brand owners. The solution aims to allow manufacturers and distributors to track raw materials, manage purchase orders, and obtain status updates on subcontractor deliveries.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Reuse vs. single use – which is better for the environment?

The ultimate guide to global plastic sustainability regulation

No comments yet