Antares Vision Group has introduced its new Food Safety Solution, a cloud-based platform designed to improve regulatory compliance, precision traceability and supply chain transparency for food and beverage brand owners.

The system was developed by ACSIS technology, part of Antares Vision Group. The solution aims to allow manufacturers and distributors to track raw materials, manage purchase orders, and obtain status updates on subcontractor deliveries, while also providing a labelling solution with the required attributes to meet regulatory compliance – particularly those involving the FDA’s Food Safety Modernization Act (FSMA).

The Food Safety Solution is said to offer full turnkey traceability for raw materials and ingredients, hoping to help brand owners vouch for their authenticity and origin. Further downstream, the platform can reportedly address stringent FSMA mandates with situation-specific labelling capabilities.

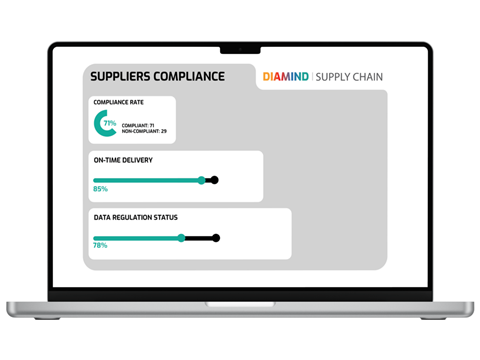

The company says the solution’s supply chain management elements are designed to help streamline procurement, production and delivery processes, simplify protocols and satisfy regulatory reporting requirements. Data collected from various metrics-producing elements hopes to help brand owners with informed intraorganizational decision-making and overall transparency.

“Antares Vision Group’s Food Safety Solution offers a versatile platform ensuring full traceability across the food supply chain, in compliance with FSMA 204,” said John DiPalo, chief strategy officer at ACSIS Tech. “By enhancing collaboration and visibility through seamless partner connections, leveraging diverse connectivity options, and integrating advanced data collection technologies (barcode, RFID, IoT), it sets a new standard in operational excellence.”

The solution is due to be showcased at Pack Expo International 2024, which is taking place in Chicago from the 3rd-6th November.

In similar news, Reelables announced the launch of its new active Bluetooth 4”x 8” shipping label back in February, apparently enabling logistics providers, cargo forwarders, manufacturers, and retailers to trace cargo through the supply chain without extra software integration. The labels track when cargo arrives and departs from a facility, what exact cargo is on a truck, and when individual pieces of a consignment or shipment split from each other.

More recently, Klöckner Pentaplast (kp) claimed it had become the first food packaging business to receive RecyClass’ Traceability Certification with a module focused on closed loop for its recycled PET (rPET) at its production site in Pravia, Spain. The company’s food packaging trays are apparently the first to be composed entirely of recycled tray material and are fully transparent.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Reuse vs. single use – which is better for the environment?

The ultimate guide to global plastic sustainability regulation

No comments yet