A new stand-alone device for a sidewall inspection in a confined space, a new generation pipeline inspector and a further developed top-down inspector: the range of applications of the pulsed X-ray technology available from HEUFT SYSTEMTECHNIK GMBH forms the main focus of the company's exhibition presence at FachPack 2018 in Nuremberg.

Three systems from the HEUFT eXaminer II series will demonstrate on stand 3-349 how carefully and precisely the integrity of product and packaging can be checked specifically and safeguarded sustainably. In addition HEUFT will show new and further developments for the exact fill level detection and leakage check of aerosol cans and plastic containers as well as for a reliable code verification.

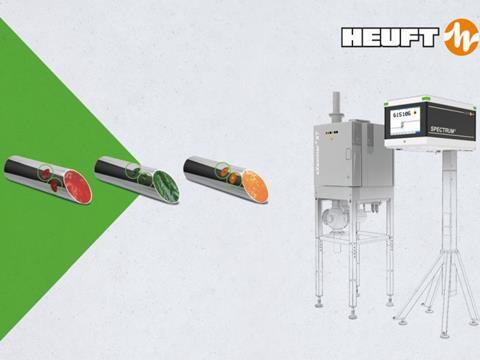

The new and space-saving HEUFT eXaminer II XS detects foreign objects reliably in freshly filled stand-up pouches, squeeze bottles or food cans. X-ray strobes which can be positioned and adjusted in accordance with the product in order to inspect it from the side provide complete coverage of the total container volume. Furthermore the HEUFT eXaminer II XT offers maximum detection and rejection reliability with minimum radiation exposure as the first highly automated pipeline inspector of the new generation for detecting foreign objects in an unpackaged product mass. The same applies to the optimised HEUFT eXaminer II XB top-down inspector which now examines even larger products and packaging material specifically for foreign objects, defects and incompleteness.

The new HEUFT SPECTRUM II ATEX especially for the non-contact fill level detection and leakage check of aerosol containers in the Ex area will also be celebrating its FachPack premiere. The HEUFT squeezer II QS removes filled plastic containers with microleaks or closure faults. And the HEUFT ONE which will also be presented live is first choice as an introduction to a reliable code verification in a confined space.