Four experts share a wide view of the factors driving innovation across the European labelling market with Packaging Europe’s Libby White.

Market trends

Nikhil Pampatwar Senior Research Analyst from the MarketsAndMarkets research company gives an overview of the European labelling market.

The demand for labels has grown in Europe because of increasing demand from various consumer product manufacturers to meet the growing demand in the market. Key manufacturers are focusing on innovating materials and technologies to improve their product portfolio and to tap into the emerging countries.

Brand owners are looking for higher performing label options that permit them to retain low manufacturing costs. For instance, heat-shrink and stretch sleeve are new label technologies that have been gaining popularity recently because of their advanced features.

Consumers in Europe are raising environment and sustainability issues against packaging manufacturers. Increasing environmental concerns have led to more emphasis being placed on the sustainability of the environment, the use of recyclable materials in labelling (especially plastic), and the use of resins derived from renewable resources. Hence, vendors are increasing investments in the development of eco-friendly label products and promoting environmental sustainability. For instance, Spear, a major label converter in Europe, has started recycling groups that collect used-up release liners after application. Other major suppliers, such as Avery Dennison, are also launching recyclable and biodegradable label products in the market. These solutions also enable OEMs to improve their brand image and reduce their environmental footprint. Increased demand for sustainability is therefore prompting businesses to explore the introduction of biodegradable products into the market.

In highly cluttered markets, creating shelf appeal and visibility is the most important strategy for manufacturers. Hence, manufacturers are prepared to invest in high quality labelling to create brand awareness and attract consumers.

Shelf appeal

Ralph Olthoff, global director for the wine, spirits and craft beer segment for Avery Dennison Label and Packaging Materials, gives us an insight into the importance of shelf appeal when it comes to labelling.

Trends differ across Europe, for example in the southern region there is a trend towards wet strength materials and luxury and premium coated materials. In Italy, there is a trend towards using black materials, (using pure black material rather than coloured black). We are seeing a trend towards bigger labels in Portugal and Austria, and in Spain. France, specifically in the Bordeaux and Burgundy areas old fashioned styles are popular, and expected from consumers. For example, it is typical to include an image of the chateaux on the label of Bordeaux wines. In regions such as the Provence there is a big trend towards using new kinds of materials and designs.

When we look at consumer groups, such as the millennials, they expect to see the story behind the product on the label. They are looking for authenticity around the product they are serving on the table. Most significantly, is how the wine makes an impact on the shelf in the supermarket. We see trends such as towards extra light materials, black materials, bigger labels, embossing, hot foils in order to attract the attention of the consumer.

To address these trends, we have launched ranges such as extra white and black materials, and a range of heavy structured materials to ensure a haptic, sensory experience. We have for example a velvet material, and one with heavy fibres that feels very thick in the consumers hands, and another made out of wood veneer which is not only visually striking but also gives the feel of the structure of wood, all designed to give a premium and special look and feel.

When it comes to labelling, Avery Dennison also has a strong focus on sustainability. For example, we focus on FSC certification and more than 70 per cent of our materials are FSC certified. We aim for this figure to reach 100 per cent in the next three to four years. We also aim to source material with either recycled content or produced from the waste of other processes, for example one material we use is made from the residuals of sugar cane.

We also encourage and implement recycling programmes for the end users of our labels whereby we collect the liner waste and recycle it into new materials We have an agreement with a paper company who recycle the waste into paper which is used by Avery Dennison.

In-Mould Labelling

Meech, specialists in static control and web cleaning technologies, shares its white paper on in-mould labelling and the role of static generation.

The label of a product acts as the corporate face of a brand, which means that poorly applied labelling (whether it is creased, inadequately aligned or displaying poor quality) can affect the consumer’s perception of product and brand. IML is an increasingly popular technology for increasing consumer appeal and protecting against contamination and counterfeiting.

One of the most common challenges encountered in the IML market is dealing with diminutive containers and labels. The solution to this problem is the creation of a miniaturised IML pinning system specifically designed for use in applications where small items are being moulded.

The Meech 994 Hydra is a system of this kind, providing powerful, repeatable pinning with no degradation over time. The components of the 994 Hydra system are easy to mount, as well as being straightforward to connect and disconnect during mould tool changes. The design eliminates the chance of sparking and the risk of expensive damage to the mould tool. The choice of materials ensures the problem of potential contamination of the container, sometimes seen with conductive foam based IML systems, is eliminated.

The standard 994 Hydra system consists of resistively coupled distributors connected in series to the new 994CG, a compact generator designed to meet the greater demands of the IML sector. The 994CG is a miniature generator with four 4-25kV outlets, making it the most powerful of its kind on the market. With feedback indicating that 24V DC power is the preferred supply voltage for ancillary equipment, the IML generator reduces power consumption, removes the need to route high voltage cables next to signal wires and low voltage cables and has a small footprint, with dimensions of 150 x 38 x 40 mm.

Adding further to the 994CG’s versatility is the ability to connect four six-headed Hydra miniaturised IML pinning systems directly to the compact generator, allowing it to be configured for multiple cavity applications.

Meeting regulations

Faye Louch, Trainer at the OAL Group focuses on how to meet regulations and why to automate.

Labelling is a legal requirement and there are regulations surrounding what must be declared on the packaging.

As consumers, we all want to know what the ingredients are in the product we are intending to buy/eat; as there may be some ingredients which as a consumer we don’t like, therefore, we would choose not to buy that product in this instance.

It is also particularly important that any allergens are clearly identified due to the risks their presence may pose to people who are susceptible and may suffer an allergic reaction, these reactions can be mild or worst case if the allergy is severe, life threatening;

The labelling of allergens is a key issue, particularly where the packaging could become detached from the product meaning the information could be lost.

You must think, worst case scenarios, where people might remove sleeves in store, for example, to look at the product and then replace them, what if they replace them on the wrong packs? This would mean the information is not right for that product. As a safety measure, in these instances, any allergen information should be printed onto the film of the product to ensure that any known allergens present in the product are still known even if the product sleeve gets lost or mixed up.

The OAL Connected system is a central database where all product profiles are set up which then allows reporting by line and by product. The system inputting is usually controlled by the technical function and the day to day running and setting up of jobs is controlled by the operational function. If the system is presented with any code other than the one it is programmed to see, the system will alarm and the line stops. This enables the site to control all their packaging very easily identify any issues; reducing and eliminating product recalls.

By scanning 2D barcodes on the packaging, manufacturers can ensure they are running the correct version of the packaging including being able to identify promo labels and slight changes of artwork.

This is the most basic package; however, the system does has other additional functionality, for example, traceability which makes the audit process smoother when establishing how much of a product has been made as well as providing downtime and efficiency data to allow sites to get an understanding of the problems during production that are causing a loss in efficiency.

For me, the control of allergens is an area where we can really help businesses as packaging ranges tend to use artwork that is very similar in design to make it look more aesthetically pleasing to the consumer and to make the range fit together on the shelf. It is getting increasingly difficult for operators to spot the difference between the different products and packaging. With the OAL Connected Autocoding system, we can ensure the product is packaged correctly by proactively verifying and scanning every product to ensure it's in the correct packaging.

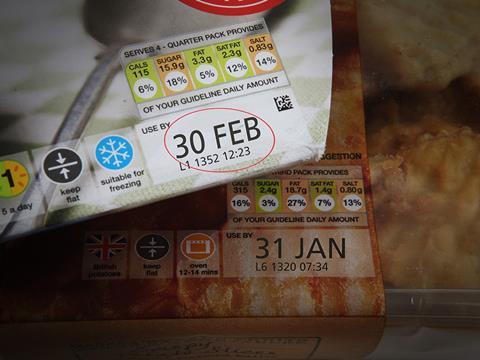

All food manufacturers are facing increased pressure from their customers to guarantee that all packaging and date coding on products is correct. Manufacturers face penalties such as heavy monetary fines and the potential loss of business for incorrect dates, packaging and labelling.

Most customers have Codes of Practice focused around coding and labelling to ensure their products are compliant with food labelling regulations. Food manufacturers have to consider a number of points when it comes to checking their packaging and applying their date codes.

Automation controls all of this key information ensuring all label, date codes, packaging and labelling is correct. This removes the risk of human errors as you are not relying on operators to ensure that all this information is correct.

Having the system in place helps businesses to protect their customers’ brands by reducing the number of product recalls.

By checking all the system alarms and fail safes are working at the start of shift means the site can run knowing their kit is functioning effectively.