Inspection technology plays a vital part in the packaging industry to prevent on-pack errors or contamination, which could result in high costs and damage to brands. Elisabeth Skoda explores innovations in print inspection, vision inspection, x-ray inspection and inline inspection with pulsed x-ray technology.

The consequences of an unwanted foreign object in a food, beverage or pharmaceutical product can be far-reaching – the costs of a product recall, for example, and the possibility of a fine from the retailer. Even causing minor irritation to the consumer can have wider implications with social media enabling any complaint or dissatisfaction to be widely shared. Underlying all this is the harm that can be caused to brand reputation.

Closed-loop print inspection

Print inspection, process control and quality assurance provider AVT and printing press supplier Edale recently presented a fully integrated closed loop image-based pressure, register and inspection system at Labelexpo Europe.

The new solution comes on the heels of the successful launch of Edale’s Autonomous inking impression Registration, or AIIR. Integrated on Edale’s FL-3 and FL-5 flexographic presses, the solution incorporates camera technology from AVT that, among other benefits, guarantees a level of registration quality never before seen in single-pass printing. After makeready, AVT’s 100% inspection system runs in the background, ensuring exemplary print quality. The configuration at Labelexpo Europe included a new feature: an integrated, image-based pressure control system.

AIIR functions as follows: Registration marks are printed on each station and fed to the AVT Helios S camera positioned at the end of the press. The camera analyses the relative positions of the marks and sends necessary corrections to the respective print stations. Sophisticated tracking software developed by Edale ensures that no additional corrections are made until the initial corrections have passed the camera.

“Working closely with Edale, we have achieved a solution that has exceeded our expectations,” says David Naisby, Business Development Director for AVT. “Together, we’ve developed a unified, Helios-integrated platform performing multiple tasks to consistently minimize waste and increase overall quality.”

The importance of vision technology

Vision technology is commonly used to inspect various packaging components for physical malformation, randomly-occurring manufacturing defects and out-of-spec dimensions or other characteristics. It can also be a vital component in protecting consumer safety and brand integrity.

Vision technology provider Pressco Technology Inc. engineers and supplies vision inspection systems with an emphasis on the manufacturing and/or filling processes of food and beverage containers. Because contamination can occur at any point in the process, distributed inspection is vital.

“In the world of plastic packaging, contamination can occur several ways: Either loose objects that ‘float’ in or on the container, or embedded material that is lodged within the plastic itself. Whereas loose contaminants pose a rather obvious hazard, embedded foreign matter may adversely impact the structural integrity and performance of the package,” Michael Coy, marketing manager at Pressco Technology. points out.

In the case of PET bottles, often the best place to inspect for foreign objects is in the preform stage. Contamination, whether loose or embedded, is generally easier to see when the geometric facets of many blown bottles aren’t yet present.

“Inspecting preforms from multiple angles inside the blow moulder and rejecting them before blowing is key,” Mr. Coy explains.

Metal packaging is equally susceptible to foreign matter finding its way into empty containers which could pose a significant hazard to consumers. Can manufacturers commonly use vision inspection to detect these foreign objects and remove the container before it is delivered to the food or beverage packing facility.

“In recent years, there has also been a noticeable shift on the part of filling companies to deploy vision systems as a final ‘failsafe’ check for foreign matter or contamination immediately prior to filling,“ he adds.

Another recent development concerns the inspection of decorated labels on metal food and beverage packaging.

“Canmakers worldwide are now investing heavily in sophisticated, high-speed multi-camera inspection systems such as Pressco’s DecoSpector 360 to check every single label of every can during the production process. One of the main drivers is the potential danger of a “rogue can” – for example, an empty soda can which has accidentally become mixed into a pallet of beer cans. Another driver is the brands’ fierce desire to remove any cans with printing anomalies which could tarnish the value or reputation of the brand,” Mr. Coy says.

The power of x-ray

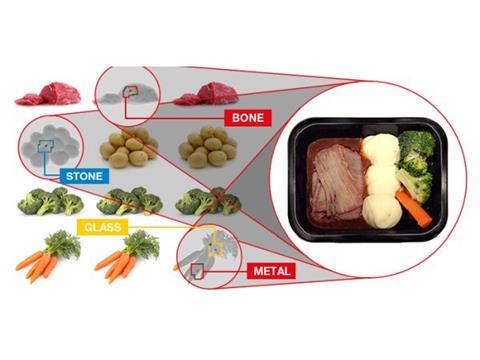

X-ray technology is increasingly being adopted for product and pack inspection thanks to its great versatility. X-ray inspection systems are able to look for a wide array of foreign bodies, including metal, dense plastics and rubbers, glass and stone, and can also carry out a variety of additional quality checks, such as missing, undersized and broken items, deformed product and packaging, under-filled compartments, the presence of cracks and fissures in products, and weight estimation.

Two important initial considerations when choosing an x-ray machine are the characteristics of the product and its packaging, and where the machine needs to be placed on the line, as Ciaran Murphy of inspection systems provider Ishida Europe points out. “Unpacked products such as raw materials for further processing, or meat and poultry, salad, vegetables and nuts may need to be screened at the very start. Finished, packed product will be inspected much further down the line. In terms of the product and its packaging, the overall size will be important in determining the choice of machine. At Ishida, for example, our range of x-ray inspection systems includes a model with a chamber height of up to 390mm, able to handle large size items such as 25kg blocks of cheese or butter.”

In addition, while most x-ray systems operate from the top down, sending an x-ray beam through a product vertically, for taller pack formats, such as bottles, cartons and tubes, side-beam x-ray models are available which project the beam horizontally. As well as foreign bodies, this also gives them the ability to check for the correct fill level and that the closure is in place.

Selecting an x-ray system with the appropriate level of sensitivity is also key, as Mr. Murphy explains.

“X-ray inspection involves the projection of relatively low energy x-rays onto a sensor or detector. As the product or pack passes through the x-ray beam, only the residual energy reaches the sensor. Measurement of the difference in the absorption level of the X-ray energy between the product and a foreign body enables the foreign body to be detected. Different x-ray models will therefore have different levels of sensitivity. Cost-effective entry levels systems, such as our IX-EN model, are able to detect foreign bodies with a reasonably high density. Softer or less dense items like glass or rubbers will require machines with greater sensitivity, such as our IX-GN range.”

Ishida x-ray inspection systems incorporate genetic algorithm software that is able to analyse image data over a number of generations to achieve a high level of accuracy. Since many applications will require the detection of similar foreign bodies, the system can be optimised to look for these objects and help to eliminate recurring sources of contamination.

Mr. Murphy goes on to explain the challenges of meat and poultry inspection, and how Ishida tackles them.

“A typical quality inspection requirement is the detection of unwanted bones in fillets. Because there is a relatively small difference in density between the bone and the meat, the bone can be particularly difficult to spot. This has led to the development of dual energy x-ray systems, which have two line sensors, one which takes images at high energy and one at low energy. This provides a better overall image of the product with a clearer contrast between the product and the bone or other foreign bodies.”

Efficient in-line inspection

In-line inspection technology plays a decisive role in protecting consumer safety, as it effectively prevents unreliably packaged or contaminated products from reaching the market. Retailers are spared costly and image-damaging recall actions as a result.

“This protects the brand and increases customer confidence in the safety of the product,“ says Heuft Systemtechnik GmbH‘s public relations editor Hilmar Wagner.

With in-line inspection, each individual product has to be examined on the line by means of a suitable procedure while still undergoing the filling and packaging process regardless of whether it is an empty container or filled packaging material. This is the only way to carry out truly continuous quality assurance. It is equally important to remove the products in question accurately and efficiently.

“Product monitoring with millimetre precision and accurate rejection systems including reject verification are needed in addition to the most suitable state of the art inspection technologies particularly in the high-speed section,“ Mr. Wagner explains.

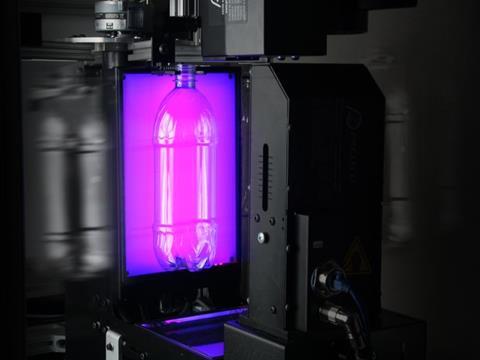

Mr. Wagner highlights the HEUFT InLine II IXS, an innovative empty container inspector with pulsed x-ray technology, which was first presented at drinktec 2017.

“This state of the art system features a specific rotation and fine adjustment of each individual bottle for eight views in each case and therefore considerably more than a 360° coverage during the camera-based sidewall inspection with double resolution. It offers unparalleled precision during the base, underchip, thread, finish and sealing surface inspection with high performance optics and HEUFT reflexx² image processing capable of learning, fully integrated, optimally arranged and safely encased detection modules including residual liquid detection. The food sector increasingly relies on systems which not only identify metal objects but also foreign objects made of a wide variety of materials. Our further optimised pulsed x-ray technology helps with maximum detection accuracy at low radiation levels.“

In conclusion, Mr. Wagner emphasises the HEUFT eXaminer II XOS which is able to find all types of foreign objects regardless of their respective position in the bottle using sophisticated camera and pulsed X-ray technology. Full container inspection is playing an increasingly important role during the drink filling process. There is a growing awareness in the beverage sector of the necessity for full container inspection, as dangerous objects can still enter until arriving at the closer.

“The compact HEUFT eXaminer II XOS identifies bits of paper, insects or film remnants which float about in the product or have sunk to the bottom of the bottle using LED strobes, mirror cabinets and colour cameras which are adjustable by motor. High resolution images are therefore produced which show the whole neck, body and base area completely. Bottle defects themselves are reliably detected with it besides low density foreign objects. It work even when the faults are covered by material structures such as embossing – thanks to the HEUFT reflexx² real-time image processing system.”