When we polled the audience at our recent Sustainable Packaging Summit to find out what their biggest concern was in terms of meeting their sustainable packaging targets, the most popular answer was clear: cost. Anna Perlina, sustainable packaging consultant at Integrity Solutions, talks us through some strategies and tactics to help companies meet this critical challenge head-on.

The cost challenge is one of the main takeaways from the Sustainable Packaging Summit 2024, held by Packaging Europe in Amsterdam.

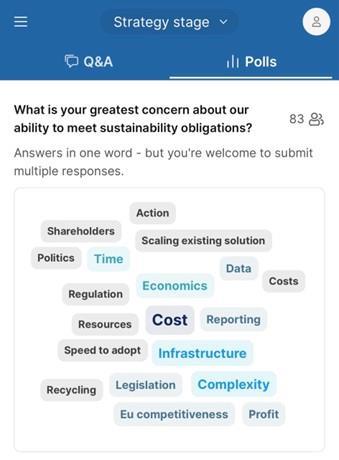

Below are the results of a poll conducted during the event, asking the audience—professionals in packaging—about their concerns.

We see the answer “cost” prominently displayed in large letters, as this is the most frequent response. Its size would be even larger if we combined it with other replies indicating similar concerns regarding economic viability, such as Economics, Profit, Resources, and EU Competitiveness.

What would be your response—your main concern?

No surprise—companies need to run their businesses. Many companies are committed to improving their practices for reducing environmental impact but may hold back because the numbers don’t add up.

The choices and implications of implementing a sustainable packaging strategy must also make sense from a business perspective. While it should be acknowledged that, in many cases, sustainable packaging is an investment, there is still room for cost-effective strategies and viable business cases.

Now that the EU PPWR (Packaging and Packaging Waste Regulations) is officially published and has entered into force, it’s time for companies that haven’t yet started their preparations to accept the challenge and explore options in a cost-effective manner.

So, what can be done?

There are ways to optimize costs while transitioning to sustainable packaging, and I would group them into the following key approaches:

1. Sponsor your change

This involves conducting preliminary work on the existing packaging portfolio and its sourcing, streamlining it to extract productivity that can be invested in the next steps of your sustainable packaging journey.

Practically, you can examine your current packaging portfolio and assess its variety and each element from the perspective of functionality and consumer desirability. This may reveal that some packaging SKUs can be standardized for economies of scale, some packaging components are unnecessary, multiple packaging layers can be avoided or merged, and lighter options may be available for the same packaging concept.

Along with cost savings, this step is likely to already reduce the environmental impact of your packaging. It also helps decrease complexity before the next packaging change, optimizing resources and effort required for the transition.

2. Revisit your packaging concept

Once your existing portfolio is streamlined and you’ve achieved certain cost and environmental reductions, it’s time to assess what else needs to be done to comply with regulations or what further actions can be taken to achieve additional gains in terms of cost optimization, consumer loyalty, and reduced environmental impact. This is an opportunity to challenge your existing packaging concept and explore what other options the market offers.

For a cost-effective approach, it makes sense to assess off-the-shelf packaging solutions and operating models that are available at scale and already appreciated by other companies and consumers.

Developing something unique that stands out while also complying with regulations will indeed make you noticeable, but it may increase your investments, limit sourcing options, and impact price competitiveness, potentially becoming a bottleneck in your supply chain.

For sustainable packaging to be economically viable and realize its full potential for environmental impact reduction, it often goes hand in hand with packaging standardization, as seen in reuse models.

For differentiation, consider other cost-effective solutions available at scale, such as labels, or further enhance your product and your sustainable marketing strategies.

In addition to changing the packaging concept, there are also options for rethinking product concepts or operating models. This already exists in the market, for example, when companies transition from liquid to dry content in their products, avoiding or optimizing their packaging to address regulations, costs, and complexity simultaneously.

3. Anticipate and streamline your future packaging value chain

When working on new packaging concepts, it’s important to keep an eye on their implications for the future value chain. Avoid creating greater supply chain complexity, don’t lock your company into exclusive commercial relationships, and don’t rush to invest in in-house capabilities. Instead, assess opportunities for packing/filling outsourcing or sharing capacity with peers to avoid or postpone risky investments. Aim to reduce the number of steps in your value chain, co-invest in capacity, and gain scale to improve costs.

4. Build your business case

This involves how to approach the ROI (Return on Investment) of your sustainable packaging projects. A longer-term perspective needs to be applied to address related business risks and include opportunities. Instead of assessing new packaging options based on the costs of materials, operation and investments, it’s crucial to consider and quantify other implications, such as the cost of inaction and the increasing demand for sustainable and trustworthy products and services.

Calculate potential savings from transitioning to more sustainable packaging. This can include reduced waste disposal fees, lower material costs if you’re able to source cheaper sustainable options over time, or savings from EPR (Extended Producer Responsibility) fees and plastic taxes, such as those being rolled out in the EU.

Consider the impact on sales due to enhanced brand reputation, customer loyalty, and meeting market demand for sustainable products. Factor in costs avoided through compliance with regulations or penalties related to environmental standards.

The path to sustainable packaging is not just about adopting new materials; it’s about rethinking how businesses operate to ensure a balanced approach. With thoughtful planning and strategies, companies can evaluate various options to transition to more sustainable packaging solutions in a way that is economically viable and effective.

If you liked this story, you might also enjoy:

Reuse vs. single use – which is better for the environment?

Sustainable Innovation Report 2025: Current trends and future priorities

What can the world learn from South Korea’s world-leading performance in plastics circularity?

No comments yet