With the Ecodesign for Sustainable Products Regulation (ESPR) expected to become operational in 2027 and the European Commission due to propose Digital Product Passport (DPP) content for certain product groups, Daniel Sabin Diaz, global senior solutions consultant at Systech, outlines how it will affect data carrier printing, data exchange and stakeholder responsibilities.

What a fascinating concept! This is not a passport for an individual person, it’s a passport for a product. The Ecodesign for Sustainable Products Regulation (ESPR) entered into force on July 18, 2024. This regulation serves as a key pillar of the Green Deal and supports Europe’s objective of becoming the first climate-neutral region by 2050.

The ESPR is expected to become operational starting in 2027, with different product classifications having varying priorities and deadlines. A recent study published by the European Commission highlights the analysis and priorities for specific product groups. Among these, textiles and footwear, with an estimated market size of €175 billion, have been identified as the first priority due to their significant environmental impact.

In the coming years, the European Commission will propose specific requirements, standards, and Digital Product Passport (DPP) content for these product groups through delegated acts, as outlined in the ESPR working plan. This new regulation is poised to affect nearly all industries, with the exception of food and pharmaceutical products, which are governed by their own regulatory frameworks. Some of these concepts are discussed in my book, Track and Trace for Supply Chain Visibility in Pharmaceuticals, Beverages, Foods, and Cosmetics. All packaging industry will be affected as data carrier printing, data exchange and responsibilities will change. While the regulation is still a work in progress and clear requirements have yet to be finalized, three critical elements will determine its success:

1. Data carrier and embedded information

2. Data exchange protocols and standards

3. Stakeholders and their responsibility

A detailed explanation will be shown below for these 3 elements:

1. Data Carrier: QR, Data Matrix, RAIN RFID, NFC?

The directions and recommendations from GS1 are to use Quick Response (QR) and Data Matrix codes. RAIN RFID and NFC will only be used as additional options if approved, due to the extra hardware, costs, and efforts required.

- Quick Response (QR). QR codes can be read by standard native cameras on smartphones. When scanned, they typically point the user to a URL and provide information directly. This ease of access makes QR codes popular for consumer-facing applications. QR codes can also be read quickly by industrial scanners and can store a moderate amount of data. They have an intricate design with three large squares at the corners to aid in orientation. QR codes are also key to the industry’s GS1 Digital Link adoption plans for 2027, which is another important initiative as part of the transition from 1-Dimensional (1D) barcodes (UPC and EAN) to 2-Dimensional (2D) codes.

- Data Matrix (DM): Native camera apps on smartphones do not currently support reading Data Matrix (DM) codes. To read Data Matrix codes with a smartphone, a specialized app is required. However, there have recently been initiatives to enable Data Matrix (DM) reading using standard smartphone camera apps. Data Matrix codes are well-suited for applications requiring compact data encoding and are commonly used in industrial and manufacturing settings, especially for healthcare products. Data Matrix codes are also square but feature a different pattern compared to QR codes and are often more compact.

- Radio Frequency Identification (RAIN) RFID is also known as Ultra-High Frequency (UHF) RFID. It is a passive, wireless technology that enables consumers and businesses to find, identify, and authenticate each item tagged with a RAIN RFID tag. RAIN RFID has the capacity to carry a GS1 Digital Link URI in a binary string. RFID tags are attached to items to transmit stored data to an antenna. This method is widely used for pallet tracking and medium-to-large equipment but is less common for small items due to cost considerations. The disadvantage is that special devices are required to read RFID data. RAIN RFID with GS1 Digital Link URI syntax is very likely to be supported in the GS1 AIDC Application Standard for DPP. However, the binary string is not yet natively supported by smartphones.

- Near Field Communication (NFC). NFC is a technology widely used for making payments with smartphones. It is also capable of carrying a GS1 Digital Link URI, and it is natively decoded by smartphones to produce a web result. However, it is not a GS1-approved data carrier at the moment. Additionally, the requirement for specialized hardware goes against Europe’s zero-emissions plan.

We took a look at the data carrier technologies that can be used to store the necessary data to tell the entire story of the product, including raw materials. It looks like QR will be the preferred option for most products.

There is another key element: what data will be on this data carrier. What is clear is that, in some cases, we must identify the product in a unique way. The following identifiers are required:

- A product identifier: as Global Trade Item Number (GTIN). This will identify the kind of product. Manufacturers or economic operators will need to request approval from GS1 to obtain a GTIN number and then seek approval from the European Commission.

- Serial Number (SN). This will identify each product amongst a group of similar products.

- Batch Number (BN). This will identify a batch/lot.

There will be options regarding the embedded data, depending on the kind of product, but a combination of SN and GTIN, as described above, is the only way to make any product unique. This is important for traceability, maintenance, and warranty returns. Adding batch numbers will provide additional benefits. This is what is required to make the product journey specific to the product.

Another important element will be the Global Location Number (GLN), which can be used by companies to identify their locations, giving them complete flexibility to identify any type or level of location required. A company’s GLN will demonstrate the ownership of the product through manufacturers, importers, distributors, repairers, recyclers, etc.

2. Data exchange:

Data Exchange is an element that is not easy to implement, yet it is always required to exchange information. When the user scans the product, different elements should be shown, such as: source, footprint, maintenance details, documentation, warranty, and instructions. These are all static elements that can be added to the passport details once the product is created. However, there are others, like ownership of the product, that will change once the product is sold.

For example, products are typically sold by the manufacturer to the distributor or importer within EU borders. This is a change in custody, meaning a new owner. If it is sold to a final customer, that could also be marked in the DPP. The physical product will change ownership, and that change should be reflected in the data when a customer scans the product’s QR code. This information should be shown in the public details shared. The owner’s traceability requirements are still in progress, and it is yet to be defined which group of products will be affected.

As I explain in my book, data exchange and integration is one of the more difficult topics nowadays due to the complexity, variety of systems, and different standards.

The manufacturers or economic operators are the main responsible parties for the DPP creation. Product identification characteristics will be added to the product, and the DPP itself will be created. It is important to note that, within a manufacturing environment, there are several challenges involved in integrating software through data exchange. Many types of software are involved in this area, and the integration and maintenance of these systems are critical to the success of DPP implementation.

3. Stakeholders:

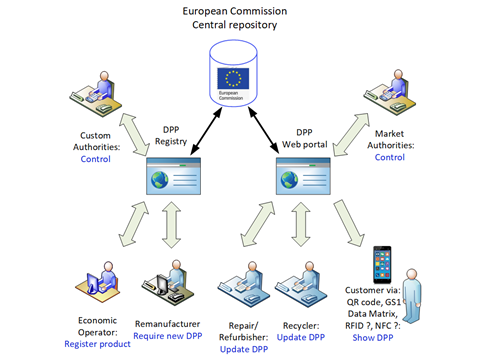

The regulation will impact several stakeholders. Almost all businesses in Europe and all businesses outside Europe that want to export their products to Europe will be impacted. This list describes some of them and their responsibilities.

- Manufacturers: Responsible for the creation of the DPP and linking the physical and digital product if they are within Europe. They will also be responsible for updating the DPP registry. For manufacturers outside Europe, the importer (economic operator) will be responsible for entering the product into Europe and, therefore, updating the DPP.

- Importers: Importers will have in some cases the responsibility of the DPP creation. In this case the importer will have to recollect all the information and data from the manufacturer to create the DPP. They will update the DDP Registry.

- Distributors: Distributors will probably need to update the location and journey of the product.

- Repairers/Refurbished: Repairers should keep the DPP as it was and only update the DPP with the required information about the repair.

- Remanufacturers: This will require a new DPP, as it is considered a new product, which means a new DPP.

- Recyclers: Responsible for consulting the DPP and probably marking the end of life.

- Market surveillance authorities: Access to the DPP to verify the data’s authenticity.

- Customs authorities: Responsible for enforcing trade regulations and controlling customs duties and taxes. They will have access to the DPP registry.

- European Commission: Central database with all DPP content and responsible for granting access to sell the product in the European market to the economic operator.

- Customers: will be able to consult the DPP at any time via a web portal.

4. Advantages of DPP:

Sustainability: The information in the DPP will allow the EU to control resources utilized and emissions released during the manufacturing process, and it will provide full details of the environmental impact of the product.

Circularity: Full visibility of the raw materials and components used within a product, along with details of which parts of the product can be recycled and reused, will enable circularity.

Counterfeiting: The DPP will reduce the efforts of counterfeiters, as the product will have a digital twin.

Diversion: Criminals will face a difficult task entering products into Europe that are supposed to be sold in other regions, as they will need to have a DPP assigned.

Customer experience: Clients will gain information about the manufacturing process, resources, and raw materials. Additionally, brands can improve their relationship with clients to increase loyalty and retention.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet