One of the biggest barriers standing in the way of truly closing the circular recycling loop is ineffective sortation technology. In this article, Ravi Sharma, Vice President of Research and Development at Digimarc, tells us more about a potential solution to this conundrum.

In many corners of America and Europe, the concept of plastic recycling is not new. For years, we’ve balanced concerning narratives about the plastic pollution crisis with the notion that, by throwing glass, plastic, and other materials into recycling bins, we are helping to abate that crisis.

In recent years, however, the real state of plastics recycling has come to the fore: only about 5% of plastics are fully recycled (i.e., repurposed for other products) in the U.S. annually, and while Europe’s recycling rate is much higher at about 35%, this means that most plastics between the two regions are discarded as waste.

Additionally, even plastics that are legitimately recycled don’t necessarily achieve full circularity (being reused over and over for the same purpose). Instead, recycled plastics are often put to alternative uses (for example, making pipes or door mats) and phased out of the recycling ecosystem. This means the demand for virgin plastic continues to rise, and the plastic pollution crisis only continues to grow.

Many U.S. states and the European Union are taking action to address this crisis. Regulatory trends, such as those laid out in Europe’s Packaging and Packaging Waste Regulation (PPWR) mandate increased targets for the percentage of recycled content used in new packaging.

These targets mean producers will need to purchase more recycled plastic to meet these requirements. This increased demand for viable plastic recyclate, will also require an increase in effective recycling technologies capable of supplying that recyclate.

One of the primary limitations in effectively closing the circular recycling loop is that the optical sortation technology currently being used for sorting different plastic resin types across much of Europe is unable to identify many of the plastic materials it sorts (mono versus multi-material plastics), and more importantly the type of application for which the plastic was previously used (whether for food, non-food, hygiene products, and so forth).

This inability of current technology to identify plastic packaging to a precise level of granularity limits true circular use. Advanced sortation is required to address this limitation.

Accelerating the global fight against plastic pollution

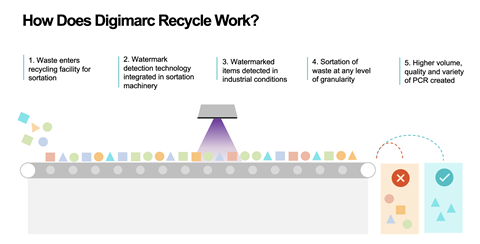

Advanced sortation technologies, like digital watermarking, can accelerate the global fight against plastic pollution by providing the level of precise sortation that makes circularity possible. Digital watermarking works by embedding a covert identifier in the packaging artwork or the substrate of plastic. This identifier is linked to information about the package, such as material type or function.

Digital watermarks in packaging can be detected at the point of sortation in a recycling facility and can accurately sort packaging based on desired criteria—such as resin types, material format, application type, or other key information. This detailed level of sortation makes the recyclate viable for resale to producers in a way it otherwise would not be.

Sorting flexible plastics

Where digital watermarks really shine compared to other advanced sortation technology is in identifying all forms of plastic, including flexible plastics (think chip bag or plastic film).

Flexible packaging is particularly difficult for other advanced sortation technologies to identify, as it loses shape and is often damaged during collection—making technologies that rely on shape ineffective for sorting flexibles. Digital watermarks are proven to effectively detect flexibles where other sortation technologies struggle to do so (4.4.1).

Digital watermarking technology has been validated for advanced sorting of flexible packaging, following rigorous industrial trials conducted under the HolyGrail 2.0 initiative.

These trials, held at Hündgen Entosorgung’s material recovery facility in Germany, focused on separating hygiene-grade LDPE films and food-grade PP films—critical components in achieving high-quality recycling streams for flexibles.

Digital watermarks are unique in their capability to accurately and consistently identify and sort flexible plastics even when the packaging has been severely damaged.

The impressive results of the HolyGrail 2.0 trials yielded detection efficiencies exceeding 95%–validating the maturity of digital watermarking technology and the potential to significantly advance the circular use of flexible packaging, particularly in the food sector.

Additionally, digital watermarks provide high reliability of detection—false identification is practically non-existent—which helps recycling plants avoid identification mistakes that can lead to lost revenue, and which are common with other advanced sortation technologies.

These successful trials prove the market readiness of digital watermarking both for achieving greater circularity and in meeting the EU’s 2030 recycling goals. This, in turn, should serve as a compelling case for other countries and brands to adopt this innovative solution.

The trials also show true promise for what the future of successful advanced sortation could look like in North American facilities, as well around the world. Given that flexible plastic accounts for approximately 50% of all packaging across the global market and is the most common type of packing in the U.S, sorting flexibles is critical to make a dent in closing the recycling loop.

Meeting the mandates

In the coming years, mandates on the use of recycled material in packaging production are expected to increase. PPWR mandates that by 2030, PET beverage bottles must be made of 30% recycled content, 10% for other contact-sensitive packaging, and 35% for all other plastic packaging.

By 2040, these mandates jump to 50% recycled content for PET beverage bottles, 25% for other contact-sensitive packaging, and 65% for all other plastic packaging. These needs cannot be met by deposit systems alone.

Advanced sorting of post-consumer waste at recycling facilities is needed to help achieve these goals. Digital watermarking is the only market-ready technology capable of effectively performing advanced sorting of both rigid and flexible plastic to meet mandates and drive circularity.

Plastic pollution is an exponentially growing crisis. Hundreds of millions of tons of plastic enter our oceans, waterways and landfills each year, and much of it is plastic that could be recycled.

We cannot wait any longer to deploy proven tools like digital watermarking. We must act now. The health, sustainability, and future of our planet depends on it.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet