In this edition of our ‘In Conversation With…’ series, Dennis Van Ijzerloo, export manager at Barberán, runs us through the evolution of digital print in the packaging space, the advantages it has over conventional printing technologies, and how packaging manufacturers could benefit from Barberán’s solutions, including its HS Series.

Could you give us an overview of Barberán’s evolution in the digital printing technology space? What would you identify as its key contributions to the sector?

Dennis Van Ijzerloo

Barberán’s evolution in the digital printing domain is marked by being the first to move into the corrugated packaging industry with their single pass digital printer. The world’s first single-pass digital corrugated printer was supplied in 2013 and since then, continuous further developments have been made trying to satisfy the market needs.

Whereas the first machines offered a 1,26 mt wide printing section running at 55 m/min with 360 dpi resolution, today Barberán produces machines up to 1,8 mts in width running at max. 120 m/min and with 600 dpi resolution and therewith closing the gap to offset quality.

Barberán has been instrumental in reshaping short-run packaging with efficiency, customization, and reduced waste.

How would you say these developments serve the packaging industry more broadly?

Barberán’s digital printing technology has played a key role in modernizing the packaging industry by empowering it to be:

- More agile

- More customer-centric

- More sustainable

- More innovative

It’s not just a technical innovation—it’s a strategic enabler of new business opportunities and operational models across the packaging supply chain.

Barberán’s pioneering technology directly addresses the real-world production realities that brands and converters now face. As average run lengths continue to fall, the limitations of analog printing become more apparent. Digital printing — particularly Barberán’s high-speed, single-pass solutions — is not just a competitive advantage; it’s becoming a necessity for economic, efficient, and sustainable packaging production.

Today, typical print runs in the corrugated packaging sector average below 2,500 pieces per job — a volume that is far better suited to digital printing than to traditional methods like flexography or offset.

Why conventional methods struggle:

- High setup times and plate costs make small runs inefficient.

- Changeovers between jobs are slow and expensive.

- Producing short runs with flexo or offset often results in cost overruns, waste, or delays.

Why digital (especially single-pass) excels:

- No need for printing plates or lengthy setups

- Instant job switching with minimal downtime

- High-speed output (e.g., up to 120 m/min with Barberán presses) makes digital viable even for just-in-time delivery

- Excellent for SKU proliferation, micro-campaigns, and seasonal packaging

Impact:

This shift to sub-2,500 piece runs is not a niche scenario — it’s becoming the norm, driven by:

- Retailer and consumer demands for customization

- E-commerce growth requiring faster packaging cycles

- Increased frequency of product refreshes and rebranding

What kinds of customers would you recommend Barberán’s technology to?

Barberán’s single-pass digital printing technology is not just for “digital-native” converters — it’s a smart investment for any packaging operation looking to optimize throughput, reduce costs, and adapt to today’s shorter run demands. Barberán’s digital presses are the perfect complement to existing High-Quality Post-Print (HQPP) or Offset equipment.

Digital becomes the ideal offload solution: Short runs go to Barberán’s single-pass press, while larger jobs stay with conventional equipment which results into freeing up of flexo/offset capacity for what it does best: long, uniform runs and therwith improving overall OEE (Overall Equipment Effectiveness) across the plant.

Have you faced any challenges in scaling up your digital print solutions?

At Barberán, scalability was a core consideration from the very beginning. Our initial engineering projects were designed with foresight, ensuring that our digital print solutions could evolve alongside our clients’ growing needs.

This proactive approach has allowed us—and our customers—to scale effectively without the limitations typically associated with rigid systems. Over these past years many of our clients have upgraded their machines with new developments made by Barberan both in hardware and software applications.

The most significant recent development is our initiative to retrofit existing machines with our latest 600 DPI print head technology. This represents a substantial technical upgrade—effectively transforming earlier 360 DPI machines into entirely new-generation systems.

For our clients, this means:

- Sharper image resolution and print quality

- Competitive edge through state-of-the-art output

- A renewed machine lifecycle without the need for full reinvestment

Tell us about a case study you’ve worked on. How did it go, and what did you find out?

With the supply of its first HS6000 to a company based out of the UK, Barberán’s together with FUJI FILM has confirmed its expansion into the graphics industry with its single-pass digital printing technology marking a new phase in digital print innovation.

Barberán’s foray into graphics brings true industrial power to digital graphics printing, and challenges the assumption that speed must be sacrificed for quality. The company is positioning itself as a disruptor, much like it did in the corrugated packaging sector a decade ago.This could mark a turning point where single-pass becomes a mainstream solution not only for packaging but also for high-volume commercial graphics — bridging the gap between flexibility and productivity in ways that few have achieved.

As with most clients, this client from the UK is also using currently several Multi-pass digital printers to satisfy their needs. These multi-pass machines have long been the go-to solution for the graphics industry. While they offer high-quality output, they are inherently limited by slow print speeds and lengthy setup time which results into a lower output. Comparing the output of the Barberan single pass printer vs the existing equipment made it obvious to the client that a quick ROI could be expected and exponential growth could be made.

For any of our readers who are unfamiliar, can you walk us through the HS Series?

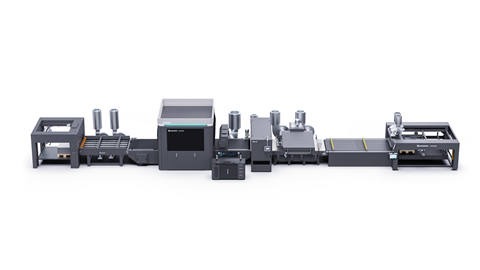

The HS Series represents Barberán’s flagship solution for high-throughput, single-pass digital printing in the graphics and commercial print space. These systems are engineered to bring industrial power, versatility, and configurability to markets traditionally dominated by slower, multi-pass printers or inflexible analog solutions.

Barberán offers the HS Series in multiple configurations, each tailored to meet the unique needs of different production environments and run-length as it can handle both long runs and high-mix, short-run production — especially for clients managing a large number of SKUs with shorter individual run lengths. Those clients with large number of orders of a lower volume would be more suitable to work with manual feeder and stacker whereas the longer runs are more favorable for automatic feeder and stacker. All of these options are on the table and each line will be configured to best fit the needs of each client.

How do you see this series evolving in the future? What progress could it make for packaging manufacturers?

One of the strengths of the Barberán HS Series is its modular, upgradeable architecture. This design philosophy ensures that customers can start with what they need today and scale up as their business grows. The HS Series isn’t just a high-speed printer — it’s a long-term production platform. By offering a scalable architecture with upgradeable feeding and stacking systems, Barberán ensures that customers can:

- Start lean

- Operate efficiently from day one

- Scale seamlessly without major reinvestment

This approach maximizes flexibility and minimizes operational risk, making the HS Series an ideal solution not just for today’s needs, but for tomorrow’s growth.

To learn more about Barberán’s Jetmaster series and the markets it serves, click here.

No comments yet