One of the most popular methods of protecting goods in transit has been air pillow film; it needs little storage space before use, can be created on demand, is cleaner and easier to use than loose fill and after use can be punctured to reduce the amount of space needed for disposal.

Pacplan® AirWave™ household-biocompostable films perform just like their polythene cousins, but when their working life is over they retire to a compost heap where they quietly disappear.

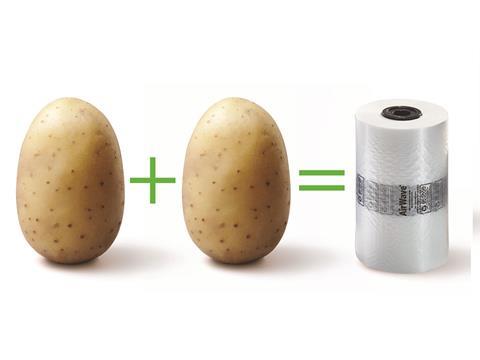

Made from biopolymers taken from waste by-products of the potato processing industry – peelings, misshapes and all the products they can’t put on the supermarket shelves which are household biocompostable.

A large percentage of ecommerce goes to households. Biocompostable is one better than biodegradable. It completely disintegrates without a trace and if anything, enriches the compost it’s added to. Household means just that – it can be added to a compost heap in the garden; it doesn’t need any special kit to compost it.

The films meet the requirements of EN 13432. Within 12 weeks it can pass through a 2mm square sieve and within six months will be 97 per cent composted, enough to dig it into your flower beds.

This is a big first for the packaging industry and another example of how innovation can make impactful changes to the global waste problem. Pacplan’s AirWave pillow fill system is compact enough for the most space-restricted packing area yet with a productivity to satisfy busy order fulfilment operations.

Southgate is confident that AirWave Biocompostable will become the preferred void fill option for the ecommerce and order fulfilment sector.

More info: