When a PET container is to undergo hot filling or post-filling pasteurization, special processing known as heat-setting is required to change the molecular arrangement of the material and provide the required heat resistance.

By Paul Atkin, Marketing Group Manager, Nissei ASB Machine Co., Ltd.

With more than three-quarters of its long history being closely associated with heat-set PET applications, Nissei ASB of Japan has the experience and solutions to fulfill a wide range of market needs.

What is a “Heat-Set” Container

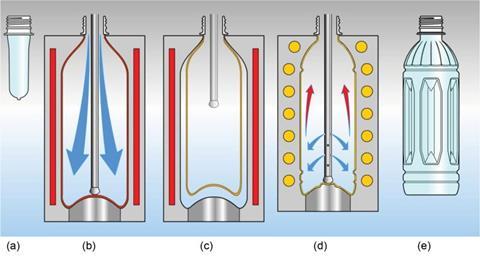

In the standard stretch blow molding process, PET chain molecules in the body of the molded container contain stress because they have been formed at a temperature which is far below PET’s melting point. This locked-in stress is what gives the PET bottle its very high physical properties, but it also means that the container will suffer increasing and uncontrolled shrinkage if subsequently heated close to and beyond its Tg (glass transition temperature) of PET (67~71°C).

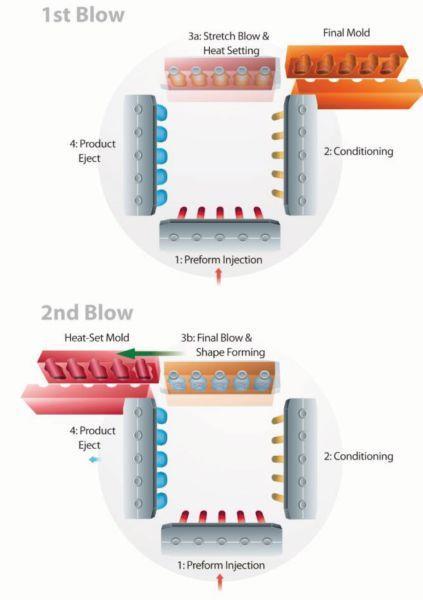

In the double-blow heat-set process, a percentage of crystal growth is encouraged to form in the body section while molecular stress is relieved by controlled shrinkage before final shaping. These two elements in tandem produce containers that exhibit up to 92~95°C heat resistance directly after molding - more than enough to allow hot filling and pasteurization of many food products.

Hot filling temperature ranges are open to many interpretations with temperatures up to the Tg of PET often referred to as “semi-hot fill” or “warm fill”. But such definitions must be used with care since it is not only the initial filling temperature which dictates performance - the total heat load on the container through the filling process varies according to additional parameters such as product viscosity and post-fill cooling methods.

Container design and processing conditions can be tailored to the needs of each application so whether the container is to be hot, warm, or cold filled followed by tunnel or batch pasteurization, the double-blow process can provide the necessary heat resistance at optimum output rates.

Molding Process

While it is possible to heat-set to some degree by modifying the standard stretch-blowing technique, to maximize the container’s heat resistance the double-blow process offers superior performance.

Technical Solutions

Nissei ASB can offer two different production routes to achieving double blow heat-setting.

ASB-**/DB Series

The recently introduced ASB-**/DB route utilizes ASB’s renown 4-station one-step machines that are specially modified with a shuttle type blow station to provide the double blow function.

Key advantages of this system are;

- Minimal investment with maximum flexibility as the machine can also be used for molding a wide range of standard containers.

- Extremely compact footprint.

Currently there are two ASB Series models that incorporate this feature; - ASB-12M/DB – ideal for small bottles or small scale production. - ASB-70DPH/DB.- ideal for production of around 0.35 ~ 2-liter class heat resistant bottles or jars.

PM-CM-HSB

This method, originally developed, then refined by ASB over many years uses a PM Series machine to injection mold the preform while an HSB Series machine re-heats and double-blows it into the final bottle or jar shape. The interim CM Series machine is optional and provides neck crystallization where product design, cap type or heat resistance specification requires it. The processes can be operated individually or as a single integrated system. Key advantages of this system are;

- Dedicated machines are optimized for peak container performance and output.

- Heat resistant jars with up to 110mm diameter neck are possible.

The line-up consists of; - PM Series – Bottle & jar preform injection molding from 6 to 48 cavities - CM Series – Bottle & jar neck crystallization from 2,000~12,000 preforms per hour - HSB Series – Double-blow heat-set molding of bottles up to ~6,000bph or wide mouthed jars up to 110mm neck diameter

More info: