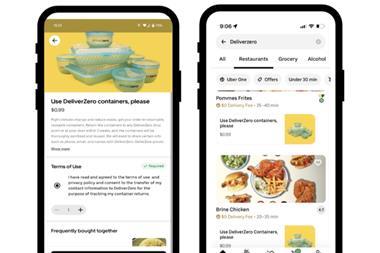

JBT Corporation, a leading solutions providers for the food and beverage processing industries, has announced the commercial launch of two innovative new solutions that have been developed to overcome challenges associated with the retort sterilisation process, namely energy consumption and water usage, and improving handling of sensitive packaging.

The Low Energy Suction System (LESS) for static 1800mm Steam Water Spray (SWS)retorts is a system capable of delivering significant energy savings by reducing retort water volume by up to 45%. The bolt-on solution, for existing and new JBT retorts, saves energy by decreasing heating and cooling costs through the use and re-use of a more limited volume of water. In fact, most companies would expect to receive a return-on-investment within two years based on energy savings.

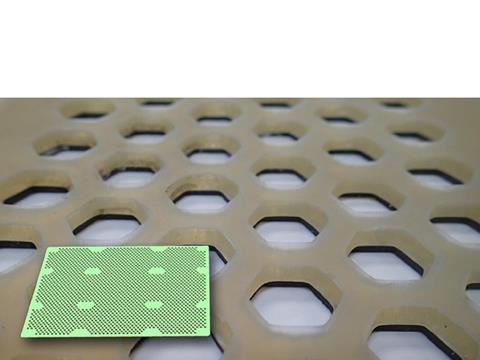

Rick Wilson, JBT’s Global Product Line Director for Retort & Rotary, said: “In a static SWS retort, the water transfers the energy to the product – if you can cut that water volume by half and run multiple cycles per day it saves a tremendous amount of energy heating and cooling the water.” The system utilises a special distributed suction that circulates the water while maintaining a high enough level to avoid complications, such as pump cavitation. JBT has also launched the Hybrid Layer Pad, a unique, innovative solution for improved handling of glass containers in baskets developed for agitating retorts. The Hybrid Layer Pad securely holds irregularly shaped glass containers during rocking or end-over-end agitation,meaning the packaging looks as good after the process as when it first entered the retort. Rick Wilson said: “Certain products, such as coffee drinks in a glass bottle, can vary in height, while also having lids with lithograph prints that can rub off on contact with metal.”

To overcome this challenge, the Hybrid Layer Pad features a spongy rubber material combined with a stiff metal base. The rubber both protects the sensitive lithograph cap from damage, and also – when the layer pad is compressed on top of the bottles – holds them securely, regardless of differences in height. The stiff metal base allows layers of containers to be swept off during unloading and prevents container sagging at the edges of the basket.“This a very unique layer pad, which has taken years to develop,” added Wilson. “It potentially eliminates the risk of breakage or damaged containers that can’t be sold.”

More info: