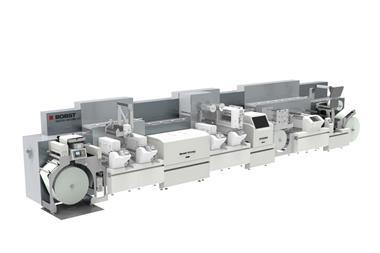

The global manufacturer of print and packaging technologies, BOBST, has revealed the NOVAFOLD, the latest addition to its folder-gluer range for packaging printers and converters.

According to BOBST, the new NOVAFOLD 50, 80 and 110 folder-gluer models are designed to help packaging companies boost capacity and end-product quality. The machines can produce a variety of box styles across a range of substrates, reportedly at speeds of up to 300 metres per minute.

BOBST says the new machine range benefits from rapid setup on all types, and most sizes, of 4 and 6-cornered boxes, apparently produced at speeds of up to 18,000 boxes per hour. The Human Machine Interface (HMI) also allows settings to be saved, with automated positioning and remote control offering precision and faster job changes, according to the company.

The NOVAFOLD can also be equipped with the ACCUEJECT complementary device, which provides enhanced quality assurance. Operating in conjunction with all commonly used glue application systems, ACCUEJECT automatically ejects boxes which do not meet the quality control specifications. BOBST claims that the device guarantees 100% ejection of faulty boxes at full speed.

The NOVAFOLD joins the VISIONFOLD 50-110, EXPERTFOLD 50-110, and MASTERFOLD 75-110 as part of BOBST’s folding carton industry folder-gluers.

Pierre Binggeli, product line director of folder-gluers at BOBST, comments: “The folder-gluer has the essential range of efficient and reliable features, from highly steady feeder through to blank aligner, accurateprebreaker, flexible crash-lock module, and 4 and 6-corner device.

“Its technology allows it to produce easily all standard packaging, opening the way towards diversification for printers and converters looking to expand their capabilities.

“There is huge market appetite for solid, dependable machines that deliver a combination of quality and efficiency alongside the robust design needed to deliver time and again. That’s precisely what converters get with BOBST machines.”

BOBST recently launched the MASTERLINE DUO – a full line solution for convertors, offering high-volume production for simple boxes and added value with qualitative printing and die-cutting.