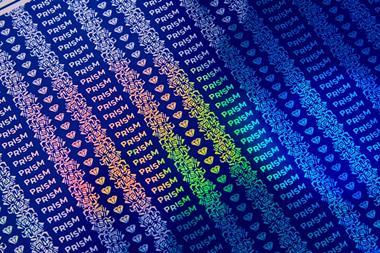

With cLynx.print, Saueressig GmbH has made a real breakthrough in digital print image inspection. The intelligent monitoring software calculates potential surface and production defects on the cylinder.

Due to an extremely fine analysis cLynx.print differentiates precisely between material defects, soilings and actual production defects. Only these are displayed at the end of the process. Stephan Lammer, Global Director Packaging at Saueressig GmbH, explains: “This in-house development enables us to optimize our production processes and to meet the high-quality requirements even better.”

The workflow is as complex as it is ingenious: cLynx.print performs a digital comparison between repro and print result. Potential deviations from the original are displayed immediately in the program and evaluated by trained personnel. If a suspected error is confirmed, a check is performed directly on the cylinder, and newly produced, if needed. The new type of inspection means that sending and check of proofings will no longer be necessary in future. This significantly simplifies incoming controls at the customer's site. Therefore cLynx.print is a measure for continuous optimization: “Another special feature is that this print image inspection system was specially developed to detect rotogravure cylinders for the smallest of defects”, says Lammers. “cLynx.print uncovers 99.9% of all mistakes. This makes us a pioneer in the international marketplace and creates a new quality guarantee.”

The software was originally developed for security printing. The internal use has been extended to the area of consumer goods packaging and promises further potentials. “However cLynx.print can also be used for error analysis on every other cylinder or similar print template. In the future we will be working on implementing this in other sectors in consultation with our customers.” SAUERESSIG GmbH filed a patent application for cLynx.print.

More info: